3D printing has huge potential for sustainable development. But if the filament used to print is made of plastic, how sustainable can it ever really be?

It’s no longer a technology of the future – 3D printing is already being used all around us. From being used to print whole houses in the Netherlands and France, to even manufacturing human noses and ears for transplants. The technology also has enormous potential in the context of environmental protection and humanitarian aid. And last but not least, it will probably turning our consumer behaviour on its head sooner or later. Why should I go to a store when I can quickly print what I need, e.g. a spare part for my broken smartphone?

But there are downsides to this development too. Being able to quickly and easily produce everything you need (or believe you need) yourself could actually end up dramatically increasing our consumption – if there are limited regulations and a lack of ecological awareness among consumers.

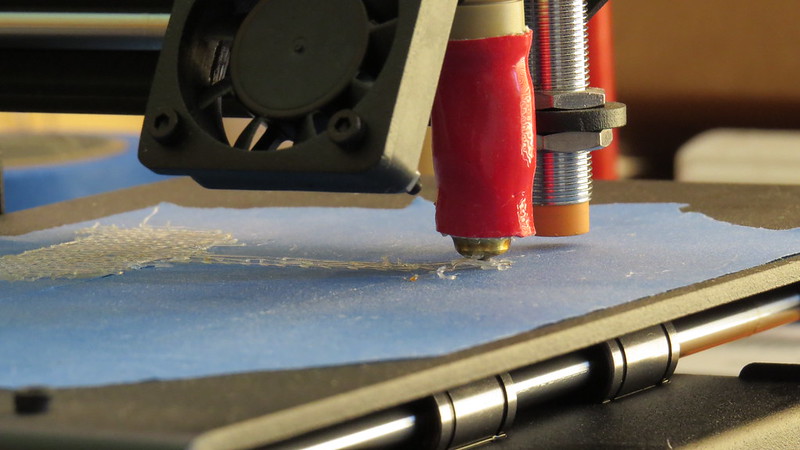

Another decisive aspect is the material used for printing. Currently, it’s largely petroleum-based plastics (ABS) that are used as filaments in 3D printing. Surely we should be trying to avoid adding to the enormous mountains of plastic waste that we are already producing (more than 300 million tons of plastic waste were produced worldwide in 2015 alone)?

Recycling vs. renewable raw materials

One approach, of course, is to recycle existing plastic waste, and turn that into the filament used in the printing process.

We already wrote about the project 3D-Wash, who are taking plastic bottles, packaging waste and similar and pressing it into small pellets which are then melted down into thin plastic threads – the filament for the 3D printer. In a second step, they can then print pipes, fittings or taps, which are used to build functioning sewage systems in (often crisis-hit) regions that are lacking in infrastructure. Another example comes from sports brand Adidas, who have collaborated with Parley for the Oceans – an initiative committed to removing waste from our oceans – to design and produce a running shoe that is largely made of recycled ocean plastic. The disadvantage of recycled material for 3D printing, however, is that it often doesn’t deliver as good a quality material as it would if using brand new, non-recycled plastics. For that reason, “fresh” plastic is often added to the filament. And the other major (obvious) disadvantage to recycled plastics? They’re not biodegradeable.

But there have long been completely plastic-free and high-quality materials available for 3D printing. One example is PLA (polylactic acid), a bioplastic obtained from sugar beets, cornflour or potato starch, i.e. from renewable resources, and biodegradable too. Recently, researchers have even managed to process industrial waste into a high-quality, biodegradable and even medical-grade bioplastic – which could also be used to 3D print medical devices such as stents and sutures. And the Canadian startup Genecis is killing two birds with one stone: by producing bioplastics from leftover food from canteen kitchens, it tackles the issue of food waste at the same time.

All these examples go to show: sustainability can only be achieved if the entire production process is looked at as a whole – the keyword here is circular economy. Want to find out more? Then check out our Knowledge article all about it.