Waste segregation and separation may seem like an unglamorous topic, but it is essential to developing a functional and efficient recycling system and minimising the burden on our environment. If garbage can be accurately separated, material can be reused and pressure on landfills reduced. Not only is this better for the environment, but the economy can also benefit from seeing garbage as a valuable resource.

Ideally, garbage sorting should start with the consumer, but it is an unfortunate reality that us humans are not always the best at understanding recycling. For example, in the US, 25 percent of all trash thrown into recycling is a so-called ‘contaminant’ – something which cannot be recycled, while 75 percent of recyclable plastic ends up in landfill. Separating out this garbage can often be time-consuming, dangerous and expensive work.

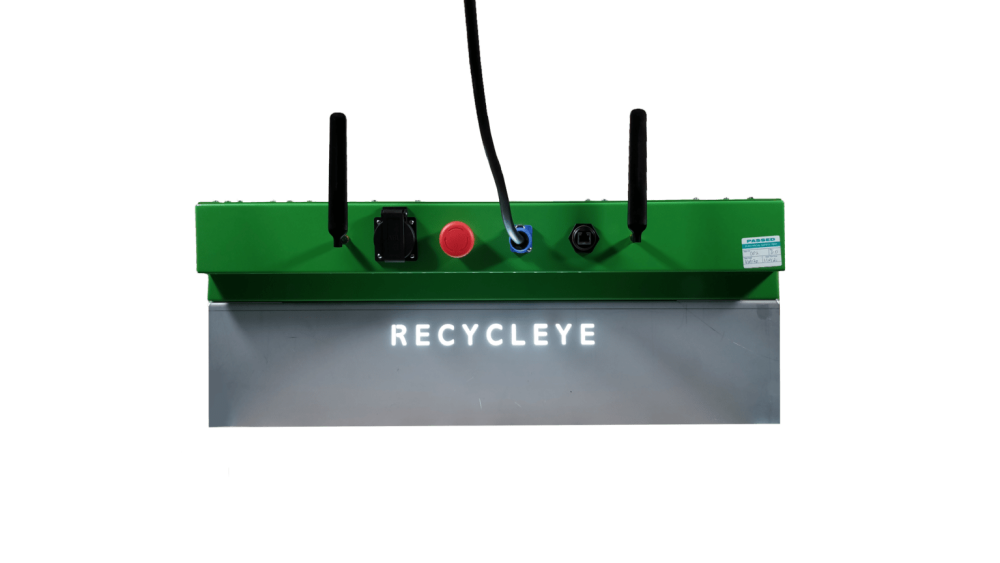

Recycleye, a startup from London, has developed a new generation of waste segregation technology that can accurately identify vastly different types of trash and even separate it automatically.

It all revolves around Recycleye Vision, an advanced computer containing a camera and suite of image recognition software. When positioned over a conveyor belt in a materials recovery facility, the Recycleye Vision accurately scans each individual piece of garbage over 100 times. Using a vast database of reference images, the camera can identify each piece of garbage in terms of its material, colour and shape, whether it is food or non-food grade or made of packaging or non-packaging materials. It is even able to differentiate between different brands.

The Recycleye can easily be installed into pre-existing infrastructure, but is also designed to pair with Recycleye’s bespoke robotic arm. According to Recycleye, the arm, which has six axis of movement, is able to pick around 33,000 objects in a single 10-hour shift.

All of these technologies are backed up by WasteNet, a vast archive developed by Recycleye and collaborating universities. Consisting of over 3 million reference images, WasteNet provides the tools machine learning algorithms need to improve their accuracy and efficiency. In addition, WasteNet also acts as the basis for academic research papers and discussions on the future of waste management, such as the development of fully automated recycling micro-factories.

Using Recycleye tools, a material recovery facility could theoretically become fully automated, likely saving millions in terms of operating costs and also making waste separation safer. Currently, waste separation is dangerous work, even in the Global North. Machines are regularly fouled by trash such as plastic bags requiring workers to reach into dangerous mechanisms. As well as being generally unhygienic, recycling conveyors can also contain broken glass, syringes and scrap metal. However, to be truly effective, automated systems must not only be speedy and efficient, but also reliable. One of the major issues for recycling centres is the regular breakdown of equipment, which results in stoppages and losses in money.

The automation of jobs is also not usually good news for those manual workers who previously worked them. When companies talk of financial savings from automation, they invariably mean a reduction in wage payments. Although developments in automation will likely result in short term job losses, there are suggestions the refinement of the recycling sector could in fact stimulate jobs. If waste products can become a cheap and reliable source of materials, it could spur entirely new industries and greatly contribute to pre-existing ones. A study from the Tellus Institute with Sound Resource Management found that improved recycling programs could generate up to 2.3 million jobs by 2030, around 2.7 times more jobs than existed in the industry in 2008.