The construction industry is facing mounting pressure to integrate non-conventional materials due to escalating demands. Traditional materials such as timber, masonry, fibre cement and metal are struggling to keep up with the current pace of global population growth. They also cause negative environmental impacts. One solution is to adopt circular construction practices focused on reducing waste, promoting recycling and using sustainable materials — biodegradable glass, for example, or recycled tires.

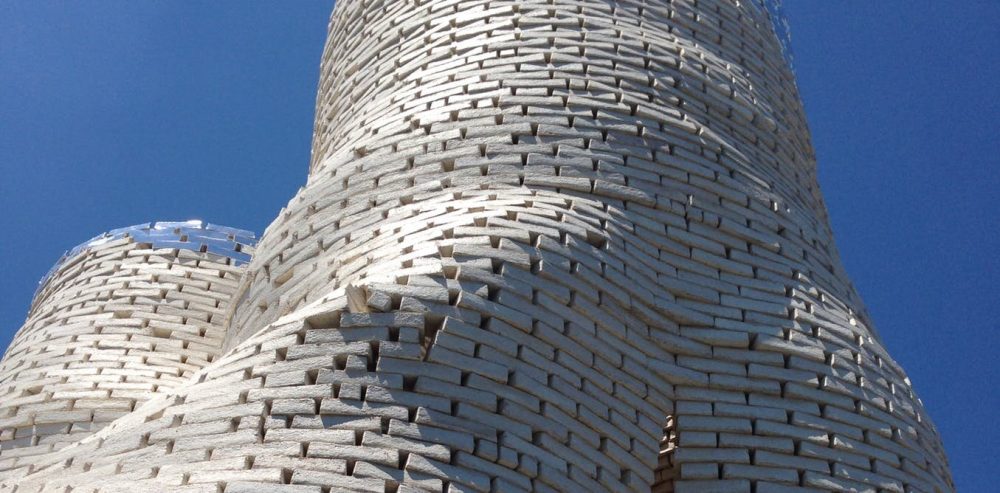

Another innovative alternative gaining traction involves mycelium, the root structure of fungi, as a construction material for bricks and cladding. Mycelium-based materials are biodegradable, consume little energy and have a low carbon footprint. They’re also relatively cheap and offer good fire, thermal and acoustic insulation. So how soon can we expect our homes to be built from mushrooms?

A super-strong, lightweight building material

Mycelium, an intricate network of fungal threads, can be harnessed as a reliable industrial material with diverse applications. The process involves cultivating mycelium from agricultural waste and mycelial cultures, then transforming it into versatile forms like bricks, panels and blocks. To create these solid materials, mycelium is mixed with organic matter, which acts as a nutrient-rich substrate. As the mycelium spreads, it digests the organic components, forming a dense and interconnected structure. This process effectively binds the mixture into a solid mass. The resulting material is moulded into desired shapes and continues growing, reinforcing its strength.

Eco-friendly packaging, furniture, art installations and textiles can all be constructed from mycelium-based materials. Increasingly, so can key components of our buildings.

Safer, cleaner cladding for residential towers

Bricks are the most obvious structural element that could benefit from a mushroom makeover. After all, concrete is notoriously resource-hungry — so much so that researchers hope producing it from diapers could alleviate sand scarcity. But while mycelium exhibits superior strength-to-weight ratio compared to concrete, its 30 psi compressive strength falls significantly short of concrete’s 4000 psi.

When it comes to buildings, cladding presents perhaps the best use case for mycelium. Recently, researchers in Australia have made strides in using fungi to produce an eco-friendly, fire-resistant outer building material. The team employs renewable organic materials to cultivate thin mycelium-based sheets that form protective layers when exposed to flames, effectively resisting fire and heat transfer.

Unlike traditional fire retardants containing harmful chemicals, the mycelium-based material burns cleanly, emitting only water and CO2. The goal is to replace hazardous aluminium cladding materials used in buildings such as Grenfell Tower.

Buildings are a CO2 heavyweight: the construction, heating, cooling and disposal of our homes accounts for around 40 percent of Germany’s CO2 emissions. We will only achieve our climate goals if these emissions are massively reduced.

But how can we achieve the sustainable transformation of buildings and what role do digital solutions play in this? The RESET Greenbook provides answers: Building transformation – intelligently transforming houses and neighbourhoods.

Mushrooming into a viable alternative to resource-hungry materials

Buildings contribute 39 percent of the global carbon footprint. Innovative alternatives are crucial. For an industry seeking eco-savvy solutions, mycelium materials have mushroomed as a potential game-changer in construction. Their natural self-assembly, coupled with lightweight and biodegradable qualities, provides a sustainable alternative to the resource-intensive status quo.

However, challenges persist. While mycelium has been utilised in innovative architectural ventures, achieving structural stability and consistent quality across applications remains a hurdle. The potential to upcycle agricultural waste and create job opportunities is promising, yet refinement and standardisation are needed for broader industry adoption. Amid these challenges, mycelium illuminates a path toward more environmentally responsible construction.