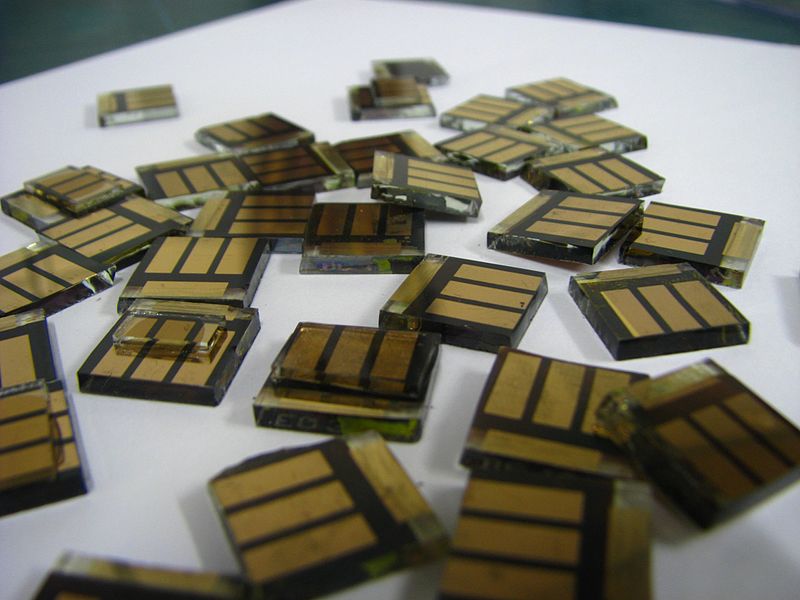

Although solar power technologies are central to sustainable energies plans, they may not be as entirely environmentally friendly as first meets the eye. For example, although perovskite solar cells (PSCs) – ultra thin and flexible solar panels – are often touted as a revolution in cheap and efficient solar power, they are not without downsides. In particular, PSCs’ commercial construction often involves lead which can, under certain weather conditions, escape into the surrounding environment.

To solve this issue, researchers at the Okinawa Institute of Science and Technology Graduate University (OIST) have been experimenting with various materials to protect the solar cells and prevent this lead from seeping out. Other researchers are experimenting with producing lead-free alternatives, but these may be of limited efficiency when it comes to actually producing electricity. Professor Yabing Qi, head of the Energy Materials and Surface Sciences Unit, who led the study explained:

“Although PSCs are efficient at converting sunlight into electricity at an affordable cost, the fact that they contain lead raises considerable environmental concern. While so-called ‘lead-free’ technology is worth exploring, it has not yet achieved efficiency and stability comparable to lead-based approaches. Finding ways of using lead in PSCs while keeping it from leaking into the environment, therefore, is a crucial step for commercialization.”

A Protective Coat That Heals Itself

To test materials, the OIST team attempted to recreate weather and environmental conditions in the lab – often with fairly simple simulations. For example, to test the effect of extreme hail on solar cells, the team smashed the solar cells with heavy balls. In most cases, the researchers simulated the most extreme conditions, which in turn would release the most lead. Once the cells had been smashed, they were drenched in acidic water – replicating the rainfall which washes the lead in the cells into the environment.

After putting the cells through their paces, the researchers used mass spectroscopy to analyse how much lead that escaped. Various materials were then pitted against each other, to see which fared best following their ordeal.

Qi’s team discovered that epoxy resin was the most effective protective layer when it came to reducing the release of lead into the environment. Epoxy also has additional benefits in that it can essentially self-heal. When placed under sunlight, the epoxy returns to its original shape and form, repairing any damage taken from trauma.

Although leakage did still occur, encapsulating the cells in epoxy did reduce it by a significant factor of magnitude, making it the most ideal material for protecting perovskite solar cells. Qi continued:

“Epoxy resin is certainly a strong candidate, yet other self-healing polymers may be even better. At this stage, we are pleased to be promoting photovoltaic industry standards, and bringing the safety of this technology into the discussion. Next, we can build on these data to confirm which is truly the best polymer.”

The next step would be to scale up the PSCs to larger solar panels. Currently, PSCs are often limited to thin strips only several centimeters in size. To be fully useful and desirable to energy consumers, they would have to grow into panels several meters in size.

Other researchers have also been working to harness the power of bad weather into their solar panels. Previously, we have heard of solar panels which can generate electricity from rainfall, with others using a similar process to generate power even when covered in snow.