Nils Lekeberg and Jesper Wirén – both from Sweden and with 25 years’ work experience in the ventilation industry – have been faced with the same problem over and over again during the last two and a half decades: the ventilation industry wastes heat at an insane rate. Usually, all of the heat that’s generated in restaurant kitchens is simply released into the air and not used anywhere else. While at the same time, around the world, air conditioning and heating systems are consuming huge amounts of energy in an attempt to heat up and/or cool down buildings all around the world. What if both problems could be combined to create a neat, sustainable solution?

That’s what the two Swedes were aiming to do when they founded Enjay in 2015, developing what is, according to them, the world’s first-ever system for recovering energy from restaurant ventilation.

How does it work?

The problem with a lot of restaurant ventilation systems is that the air from kitchens is often very dirty. The grease and soot particles in it often end up sticking to the equipment, clogging it up and damaging it. So, as Nils Lekeberg explained to RESET, Enjay has developed a three-step system that not only recovers waste heat and turns it into energy, but also solves that problem and make the whole thing maintenance-free.

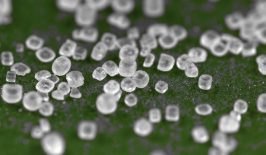

In order to be able to recover the energy, Enjay’s “Lepido” system contains a uniquely-shaped battery. Made up of hundreds of parallel strips, this design allows for most of the grease particles to easily follow the air stream and thus pass straight through the battery coil, rather than colliding with, and getting stuck to, the metal surface. When the exhaust air passes through this battery, the energy from the air flow can be stored in the coils, with minimal build-up of grease.

The few fat particles that do still end up sticking to the coils can be removed later on by the self-cleaning system that becomes active once a day. According to Lekeberg, the system doesn’t require harsh chemicals to clean it, or any kind of physical labour – instead it’s cleaned via “the forces of nature”. During the fully automated cleaning process, which is activated once a day, a central control system alternately heats and then cools the metal surfaces in a carefully monitored sequence.The fat and soot particles lose their stickiness and fall to the bottom of the battery box. And at the end of the cleaning process, in a third step, the grease and dirt mixture is cooled down again until it is solid and non-sticky, before it is transported out along with condensation water through drainage pipes that are connected to the grease separator in the restaurant’s sewage system.

Two Birds – One Stone

The heat energy that is recovered via the Lepido system can be put back into the building via a heat pump and used for heating, air conditioning, hot water or ventilation. According to the company, the system can easily be installed in all existing ventilation ducts.

Restaurant and property owners could not only save money with the technology in the future, but also significantly reduce their CO2 emissions. According to Enjay, savings of up to 123,000 kWh would be possible in a burger restaurant, for example. A hotel complex with several restaurants could even save more than 500,000 kWh.

The idea of using buildings’ excess heat is nothing new, however. In Dresden, Germany, Cloud&Heat is using the waste heat from data servers to heat water and cool the servers at the same time. And Denmark’s Refarmed is currently developing a building-integrated agriculture project in Copenhagen where all of the “waste products” from a shopping mall – from heat to organic waste and water – are reused to support the cultivation of a vegetable garden on the building’s roof.

This is a translation by Marisa Pettit of an original article that first appeared on RESET’s German-language site; co-authored by: Sheena Stolz