With Christmas fast approaching, you can soon expect countless pieces of obsolete consumer technology – phones, laptops, games consoles etc – to be consigned to drawers and cupboards never to be seen again.

Across the globe, huge amounts of electronics sit idly by, while those which are thrown out are often disposed of irresponsibly. According to a survey by Nokia, around 44 percent of old phones are left sitting around homes, four percent are disposed of in landfill and only three percent recycled.

These figures highlight the common issue with recycling electronic goods. According to the UN, around 50 million tonnes of electronic waste (e-waste) are produced each year, with only a fraction being recycled. An important issue is the complexity of these devices and the materials of their construction. Many are simply not cost efficient to properly dismantle and recycle, meaning many remain in landfill or are incinerated.

However, a team from the Johannes Kepler University in Austria is turning to nature for a solution. In a recent study, published in Science Advances, they have developed a new material from the humble forest mushroom which could be used to replace plastic circuit boards in certain electronics.

Generally speaking, circuit boards are plastic plates housing a complex array of microchips, transistors and other components. These plastic boards are a major hurdle to recycling, with many end up simply incinerated. A mushroom-based board would not only be able to decompose, but would also reveal other useful components for recycling.

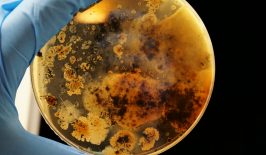

The source of the discovery comes from unrelated research. Another team was looking into the viability of wood mushroom composite materials for insulation. Previously, similar methods have been made to make sustainable leather and Styrofoam-like packaging materials. Researchers found that the inedible Ganoderma lucidum mushroom grows a compact protective skin around the wood upon which they grow. When removed, this thin film resembles sheets of paper,

The ‘skin’ is then passed through a production process to strengthen the material. When dried, it can be folded and bent up to 2,000 times without compromising its strength, flexibility or current- and heat-resisting properties. Electronic circuits and components could also be installed on the skin, making it overall an ideal circuit substrate.

The mushroom circuit is also in the “sweet spot” for biodegradability. If kept reasonably dry it will remain functional for a long time, however if placed within a standard household compost, it can be broken down in two weeks or less. Additionally, no special facilities, chemicals or processes are required to degrade the material.

Previously, other biodegradable circuit substrates have been made from paper and silk, however the Johannes Kepler team suggest these come with downsides. Growing and processing the materials is complex, as well as energy and water intensive. Meanwhile, the mushrooms cultivate and grow easily on waste wood and do not require extensive processing.

But one downside is that the mushroom-based circuit board is not as long lasting as a traditional plastic one. With this in mind, the team suggests it will best be used with certain short-life quasi-disposable electronics in mind, such as sensors, electronic tags and health monitoring devices.

But its applications do not stop there. The team has also used the mushrooms to produce a disposable, biodegradable battery. The mushroom skin was soaked in a conductive liquid electrolyte, while metal electrodes were installed on either side. When encased in a dry mushroom skin the battery could be used to power small devices such as a Bluetooth module or humidity sensor.

Not only are un-recyclable electronics bad for the environment, they are also a waste of potential resources. Many devices, such as smartphones, contain valuable minerals including lithium, cobalt and gold. Instead of simply extracting more of these materials in large-scale mining operations – sometimes in nations with poor workers’ rights and protection – these minerals could be extracted in so-called ‘urban mining’. Of course, perhaps the best way to reduce e-waste is to attack it at its source, by encouraging the use of longer lasting models with legacy support.