LAM’ON has come up with a biodegradable and compostable alternative. It looks and feels the same as conventional plastic laminating films, can be made using the same machines – and crucially, costs the same too. The startup was set up in 2017 by Bulgarian entrepreneurs Gergana Stancheva (an illustrator) and Angela Ivanova (a photographer) as part of the EU’s Climate-KIC Accelerator programme – where the founders received initial funding to develop their idea. Since being joined by biopolymer specialist Philip Ublekov, they’ve developed the idea even further, and are currently one of just 20 finalists in the running to win the Chivas The Venture acceleration competition and a share of the 1 million USD funding prize.

RESET talked to co-founder Gergana to find out more.

What’s the problem that LAM’ON is tackling? And how?

LAM’ON has developed a 100% biodegradable laminating film for the print industry – to replace all the plastic that is currently being used. Laminating film is basically a thin plastic layer that is put on top of paper in order to seal and protect it, as well as make it more flexible and durable. It’s used on all kinds of products – magazine covers, menus, brochures, catalogues, business cards… And a lot in packaging as well. Right now, the film used is nearly always petroleum-based plastic. The result is a mixed media – plastic and paper stuck together – which is difficult, and expensive, to separate. So while non-coated paper is easy to recycle, laminated paper ends up going straight to incineration or landfill. The result is environmental contamination, microplastics and two different resources being wasted at the same time. Our LAM’ON film alternative is biodegradable and even suitable for composting.

So paper laminated with LAM’ON can just be thrown in the compost bin?

If it’s applied to toxic-free, compostable paper, then yes, you can put the whole thing right in the compost bin. If it’s put on standard paper, then the whole thing belongs in the paper bin. We’ve come up with a water-soluble adhesive that is used to stick the biodegradable film to the paper. That makes it easier and cheaper to separate the paper from the film. The paper can then be recycled, and the film composted. But ultimately, wherever the LAM’ON laminated paper ends up, it’s less harmful for the environment because there are no toxins in it.

When did you realise that the print industry had this toxic plastic problem?

As long as Angie and I have worked in the printing sector. Currently, to laminate paper you literally take a roll of plastic, add chemicals, heat it and and stick it to the paper. So called “VOCs” (volatile organic compounds) are released from that when you use it. And because the ventilation in print houses usually sucks, you end up breathing all of that in. We originally set out to develop a green, plastic-free alternative – that didn’t smell like death! It was only after doing more research that we realised there was a big underlying recycling problem too.

What is your alternative made of?

Corn, basically. A biopolymer made of polylactic acid which is synthesised from corn starch. Polylactic acid has been widely used as a biopolymer in medicine and there are also packaging films made of it. It was an obvious choice for us. But then we were faced with the problem that we couldn’t find a glue that would make it stick to paper like plastic does. That’s when we set out to find the third person on our team, Philip, who has a PhD in polymer engineering and years of experience. He helped us develop a glue that would meet industry standards, be non-toxic and be made from renewable resources. That adhesive layer is LAM’ON’s biggest innovation and the way we combine the film with the glue is new too. So it’s a two-part innovation that in the process of patenting now.

Could LAM’ON also be used for other things besides the print industry? What about other types of packaging that uses coated paper and card – like coffee cups or paper plates?

Theoretically, yes. We’re planning to go into packaging later on, but we wanted to start with an industry that we knew better first – and one that people aren’t talking about as much. Everyone is trying to figure out packaging solutions, but nobody is talking about the print industry, and it’s huge!

Do you have any figures on how much plastic waste the printing industry creates?

Finding statistics on that was a huge challenge, actually. The printing industry is the 5th biggest production industry in the world, worth 8 billion euro just in Europe alone, but it’s also the most fragmented one. There is no central database. So all of the information we have is from individual print houses. We’ve interviewed around 200 experts from the sector and collected information from them. One big print house told us that they use around 10 tons of laminate film a month. And in Europe there are 120,000 companies working with print, so doing the calculations from those numbers – it’s a lot of plastic!

Where is the focus of your research?

We’ve chosen Germany as our first market bcause of the way that people take care of their waste there and the behaviour that is already in place around recycling. The end customer already cares about certification and what they’re buying. We’ve had interest from the UK and Austria too. And Bulgaria too, obviously, as that’s where we’re based and where we’re from. We’re starting with those 4 countries and growing from there.

Everyone always says that print is dead, the industry is shrinking. Is that true?

Not really. You always hear that – the printing industry is dying out and technology is taking over. There was a quite a dip a few years ago but more recently its been stable and even growing – especially outdoor advertising and catalogues and paper packaging. Nowadays with the spread of non-verified news on social media and on the internet in general, it’s been shown that people respond better to advertising and information on printed media sources. Some people predict that printed media will have a comeback soon. It’s still a billion dollar industry – and it’s not going anywhere.

So your solution doesn’t require special machines, is available at the same price and is better for the environment and human health than the standard options. Why do you think nobody ever developed it before?

Firstly: a lack of consumer pressure. It’s an invisible problem so there was no pressure from the general public. But now people are more and more concered with what they’re buying and customers are driving that kind of change. And publishing houses have their own sustainability goals – targets they want to reach by 2020 or 2030 – so they’re really interested in this kind of thing now.

Secondly: there were some alternatives already available, other laminating films that were certified as biodegradable. But they were made of standard plastic mixed with starch and other things. The material degrades but doesn’t biodegrade. They ended up being an even bigger problem, and they were more expensive than conventional films too. So the “eco” options were out there, but they weren’t being used and that was enough “proof” that nobody wanted them! Now, that’s changed and there’s definitely new demand.

Sounds like it’s the ideal time for LAM’ON to appear on the scene! But you must have faced some challenges too. What have been the main ones along the way?

The first big challenge was developing our idea into an real viable product. Originally all we had was an idea – we didn’t know how to make it into reality and develop the technology. It was really hard for us, as two young women, armed only with an idea, to go out there to try and convince people to devote time and effort (unpaid!) for the sake of saving the planet and maybe making some kind of money later on down the line. And then we found Phillip, our third member. We were really thankful to find someone with the same mindset, who sees things the way we do.

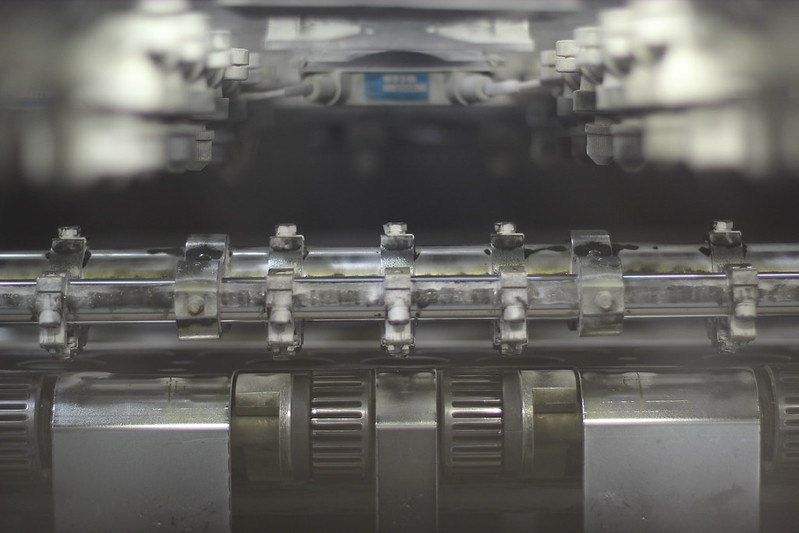

The second big challenge was finding a place to test on the big machines. Our first prototype didn’t translate to big scale production at all. We had to find a company that would shut down their machines to let us try and create something – something that they were absolutely sure wouldn’t work!

How did you manage to convince them?

By being really annoying! And by being really sure of ourselves and our product and telling them that biopolymers are the future and they have to learn how to use them. In the end, they agreed that it was in their interest to let us do the tests there and let their workers learn with us.

And of course, funding was a challenge too. When we only had a lab-based prototype when we took part in Climate KIC’s programme. We used the 15,000 euro funding to pay for the raw materials, finalise the prototype and prove it would work. Up next is pilot testing.

What is the next step for LAM’ON?

Getting our own laminating machine so that we can close the production cycle in house. Then we can work on improving the product, producing different finishes, working with different print houses in Bulgaria, getting feedback and testing. By autumn hopefully we’ll be able to sell the first batches. We already have clients waiting.

And what about your name – what’s the meaning behind it?

At the beginning of this process, we were trying to solve the plastic lamination problem by looking for things we could use instead – so avoiding lamination completely. But in the end we ended up innovating the laminating process itself and coming at it from a new perspective. So what we’re saying is, carry on laminating… LAM’ON!