Whether it’s trousers, a T-shirt or a scarf – when we get a new piece of clothing, it’s difficult, if not impossible, to find out where it was made, under what kind of production conditions and with what environmental impact. There are numerous different textile certificates and seals designed to inform consumers about all of these things, but the majority of textile companies choose not to use them. And there is still a lack of consideration for the environment, and numerous examples of inhumane working conditions found in many textile industry supply chains.

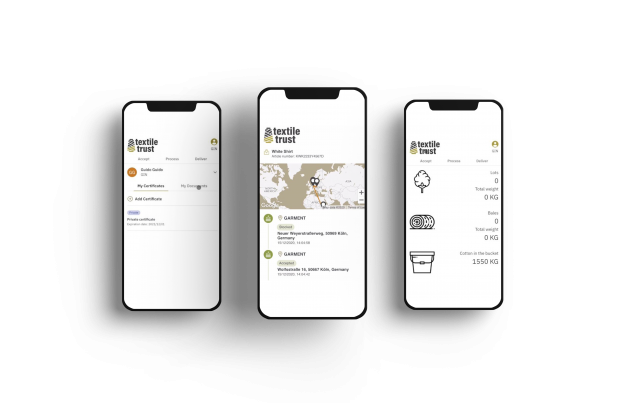

Now the German Federal Ministry for Economic Cooperation and Development (BMZ) and a team of companies are collaborating on plans to make supply chains in the textile industry more transparent in the future via an openly accessible platform. Texile Trust will display important parameters such as production standards and certificates, thus contributing to greater transparency in the flow of materials, as well as simpler administrative processes and certifications in the long term.

Transparency platform uses blockchain technology

The Textile Trust platform is based on a blockchain – a continuously growing list of records of data, called “blocks”. The blocks are linked together in a chain using cryptography, managed by a cluster of computers and blockchains are designed to be resistant to modification of its data. In the case of textile supply chains, the blockchain platform is designed to store information about the different steps in the production process. To help build the blockchain-based platform, the project is being supported by the company IBM Blockchain.

The project is led by the company Cotonea, which processes exclusively organic cotton and, according to its own statements, uses it to produce fairly produced textiles. Having itself been involved in setting up its own organic cotton cultivation projects, the company is now bringing content expertise to the project. “A project like Textile Trust has to involve all stages of the textile chain,” explains Cotonea CEO Roland Stelzer. “The know-how can either come from several contributors who represent their respective, already complex production steps and have to build a common understanding – an ambitious task – or the content can come from one of the few cross-sector manufacturers of organic cotton textiles like Cotonea, who also understand the places where the different steps overlap.”

Another partner in the project is the company Kaya&Kato. The Cologne-based company produces workwear from sustainable fabrics such as organic cotton and a polyester-cotton blend made from recycled marine plastic. On its website, the company provides an overview of the origin and production of the garments, which are made exclusively in Europe.

The project, consisting of the browser and an associated app, is to be completed by mid-2022. A demo version has already been developed, the refinement phase is now beginning and other interested parties from the textile industry are being sought to participate in the development process.

Supply chain law and the danger of greenwashing

Bringing more transparency to the supply chains of the textile industry is an important step towards making the issue more accessible and clearer for companies themselves and for consumers. But even more important than transparency is for real change to happen in the textile industry and that companies that fail to live up to their responsibility for the environment and people are held accountable. For some time now, the German Federal Ministry for Economic Cooperation and Development has been advocating for the enforcement of a supply chain law to curb environmental pollution and human rights abuses in corporate supply chains. So far, however, the law has failed due to a lack of majorities and strong criticism from companies.

The idea behind certificates and textile labels for environmental and human rights standards is also a good one. However, it is also important to look closely at what is behind each of them. The managing director of Cotonea, Roland Stelzer, is also aware of possible loopholes: “At Cotonea, we see trustworthiness – trust – as one of the most important values,” he says. “There is an increasing demand for environmentally friendly products whose production is carried out in a fair way and for the benefit of all parties involved. That makes falsifying certificates, greenwashing or simply omitting facts increasingly attractive.” That’s why it’s important to work with “watertight tracking systems,” he explains. The Textile Trust project aims to provide just that: tamper-proof data on the manufacture and production of individual textile products.

This is a translation of an original article that first appeared on RESET’s German-language site.