The research group, headed up by Dr Luis Fernando Velásquez-García, has looked at methods of growing wood-like plant tissue within a laboratory environment in a manner not too distinct from lab-grown meat products. They’ve set out the results of their research in a new report.

To achieve this, the research group took cells from the leaves of the zinnia plant and then cultured them in a liquid growth medium, which allowed them to metabolise and multiply without the need for soil or natural sunlight. These cells were then transferred into a gel substance and ‘tuned’ with certain hormones to exhibit the desired properties. In this case, two plant hormones, auxin and cytokinin, were used to manipulate the production of lignin, an organic polymer that gives wood its firmness.

The work is seen as a continuation of the microfabrication techniques being developed by the Velásquez-García research group, and builds upon previous research into other additive manufacturing methods like 3D printing. The gel in which the cells are further grown can also act as a sort of scaffolding, meaning theoretically, the wood-fibres could be grown into any particular shape, removing the need for assembly.

A way to reduce wood waste?

One of the main inspirations behind the idea was the desire to find a more efficient, strategic and streamlined way to use land and resources. Researchers observed that in both the logging and the agricultural industries there are large volumes of waste, especially in regards to the processing of timber products. If timber could essentially be grown into its final shape, it would remove the need for processing and sawing, and remove the waste involved in those steps.

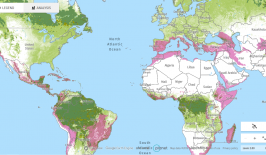

Although timber plantations can have obvious environmental benefits, such as carbon sequestration and soil health enrichment, they are sometimes monocultures which limits their positive impact. It has been suggested that if alternative forms of timber can be produced, commercial forests can be allowed to grow wild again, increasing their environmental benefits.

Currently the demand for cheap timber – especially for furniture and construction materials – is placing increasing pressure on forests around the world. According to the United Nations Food and Agriculture Organization, the wood-based panel trade alone has risen by over 800 percent in the last three decades. Timber plantations need vast areas of land, which is becoming increasingly limited in the face of other demands, such as food production, housing space and environmentally protected areas.

Although only accounting for 5 percent of total forest space, industrial plantations provide around 35 percent of global wood production. These are usually well-maintained and operate on a sustainable basis, however the demand for cheap wood has led to an increase in illegal logging. Currently, around 10 percent of the global timber trade is believed to come from illicit operations, with around half of this amount occurring within threatened forests and jungles. Natural woodland has also been converted into so-called ‘fast-wood’ forests to meet demand, with some resulting in local social and ecological impacts.

Currently, the MIT project is still in its very early stages, and the team admits it is still very far from being market-ready. The next step will be to try and increase the scale of production, as well as further fine-tune the hormone levels and pH of the gel. It is also quite possible that alternative plant cells may require vastly different ‘tuning’ settings.

The MIT report also accepts that producing wood in a laboratory setting may in fact be more inefficient than growing it in plantations. Afterall, natural timber production uses the sun’s energy and natural rainfall for production, and does not require buildings, heating or artificial lights – all of which come with energy demands.

Ultimately, however, with lab-grown organic products becoming more commonplace, savings could perhaps be made in the energy expended in timber processing, transport and treatment.